Table of Contents

[ad_1]

The National Aeronautics and Area Administration (NASA) declared April 15 it has awarded Lawrence Livermore Countrywide Laboratory (LLNL) and a private company with funding to create LLNL’s innovative volumetric additive producing (VAM) 3D printing technology to develop synthetic cartilage tissue in place.

The award, a single of 8 initiatives selected by NASA’s In Space Production Apps (InSPA) program, will allow for LLNL and Kentucky-based mostly area daily life sciences company Area Tango to experienced prototypes of the “replicator” technology—a ultrafast 3D printer co-made by LLNL and the College of California, Berkeley—for bioprinting in microgravity on the Intercontinental Space Station (ISS). The VAM printers are be expected to work with minor to no crew intervention.

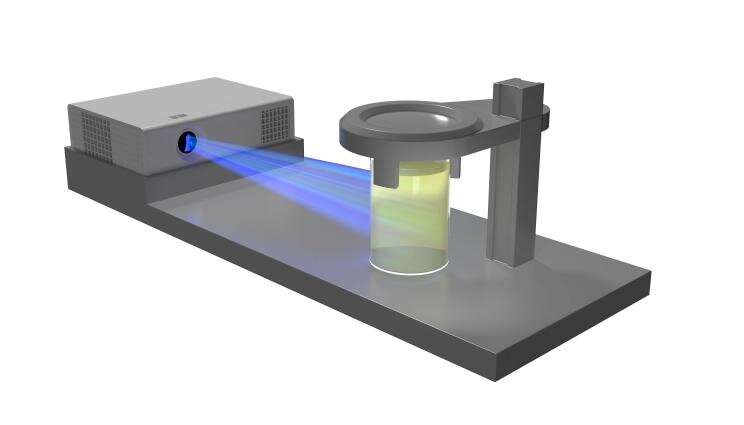

The breakthrough VAM know-how will take computed tomography (CT) “views” of 3D objects from numerous angles, and projects these pictures into a photosensitive resin. The resin cures at points the place the amassed, absorbed light-weight energy exceeds the gel thresholds, and when the remaining liquid resin is drained, it creates 3D objects within just seconds or minutes, substantially a lot quicker than standard layer-by-layer 3D printing methods.

“This proposal is important simply because it builds on LLNL’s inside investments in this spot over the final few years,” stated LLNL principal investigator Maxim Shusteff. “Place Tango’s participation highlights the assure of the VAM know-how, and connects us with the business spaceflight business. In addition, space-based mostly producing has been of curiosity for several several years for the LLNL 3D printing community—and for me personally—so starting off to construct a plan in this path is enormously exciting.”

LLNL’s partner in the endeavor, Room Tango, has several years of practical experience in building automated microgravity experiments in the pursuit of producing overall health and technologies methods in space. Considering that their first commercial launch in 2017, House Tango has done nearly 200 experiments on the ISS that goal to enhance lifestyle on Earth.

“Microgravity is a system for innovation, and it makes it possible for us to think creatively about the constraints gravity can have on Earth-primarily based research,” explained Place Tango Main Tactic Officer Alain Berinstain. “With the possibility to develop on current bioprinting tactics in a quite new way, House Tango is thrilled to husband or wife with LLNL to likely find human well being options that would not have been doable on Earth.”

The InSPA awards guidance NASA’s programs to enable production “In Area for Earth” on the ISS, to acquire new and promising technologies for highly developed products and goods for use on Earth, and create a robust economic climate in lower-Earth orbit. Whole InSPA funding for the round of 8 assignments was about $21 million.

Shusteff stated VAM is predicted to perform especially very well in zero or micro-gravity environments since reducing gravity, which can lead to buoyant settling or convection of the resin when printing on Earth, will create greater-precision prints, and let scientists to concentration notice on resolving other technological worries.

Shusteff included that tissue engineering with VAM could be just one spot wherever spaceborne manufacturing in microgravity may possibly noticeably advantage the outcome.

“Cartilage tissue was picked as a superior equilibrium of current market need to have, influence to patients, technological feasibility and our offered skills,” he stated.

Quotation:

NASA money lab to exhibit ‘replicator’ 3D printer to develop cartilage in room (2022, April 21)

retrieved 28 April 2022

from https://techxplore.com/information/2022-04-nasa-funds-lab-replicator-3d.html

This doc is subject matter to copyright. Aside from any truthful working for the goal of non-public study or investigation, no

part might be reproduced with no the written authorization. The content material is provided for facts reasons only.

[ad_2]

Supply website link